YOU LIKE TO HAVE PARTS AS LIGHT AS A FEATHER,

ENSURING ABSOLUTE PRECISION AND RELIABILITY?

Then you are with the right company.

The OSSBERGER PRESSBLOWER Techniques enable the production of bellows, shock absorber applications or boots with minimal tolerance ranges. Our machines achieve excellent results in consistent reproducibility and with low maintenance. The extreme precision of our procedure allows to save material and weight.

Our solutions

PRESSBLOWER DSE 80, DSE 150 and DSE 260

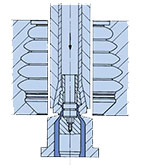

The PRESSBLOWER machines DSE 80, DSE 150 and DSE 260 are recognized in the market as solutions for the production of rotationally symmetric bellows. The machines stand out for their compliance with the smallest wall thickness tolerances as well as highest quality in series. Different product dimensions and weights can be realized on the respective machine types.

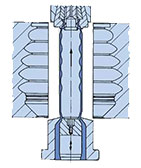

PRESSBLOWER SB2-150

Type SB2-150 is a version of the PRESSBLOWER Injection Blow Moulder, designed for bigger lot sizes. The machine works on two production stations at the same time. In addition, by optimizing the motion sequences the cycle times achieved by the previous type SB2/60 can be shortened. The attached switch cabinet reduces space requirements.

The process

The PRESSBLOWER process combines several techniques. It hosts the advantages of both the injection moulding and the blow moulding technique in one single machine. The process stands out by achieving exact connecting ends and perfect material distribution in the convolutes.

First of all, the headpiece is injected, then the injection mould moves up, and a dosed quantity of plastic is extruded, forming thus a tubular parison with an exact wall thickness distribution. In the next step, the blow mould closes around the parison, blowing it to the desired form with compressed air.

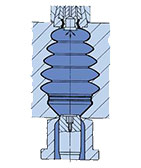

Boots

Application:

drive shaft, inboard

Material:

TPC-ET

Steering boots

Application:

steering system

Material:

TPV

Protective tubes for shock absorbers

Application:

shock absorber

Material:

TPV

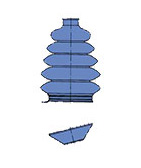

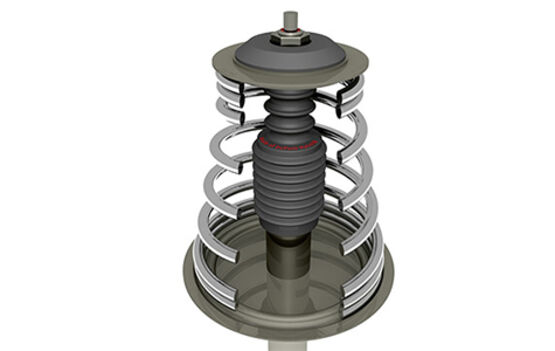

Jounce bumpers for suspension struts

Application:

suspension

Material:

Hytrel (TPC-ET of Du Pont)

Example of a suspension

References

There are hardly any cars on earth without OSSBERGER products. Almost all cars produced worldwide contain bellows made on OSSBERGER machines. The global market leadership is also a consequence of the cooperation with the internationally most important material manufacturers (see references of common projects).

Development and innovation

Today's development is tomorrow's success. Ossberger is always committed to the testing of new applications. In doing so, we are the natural partner of the globally most important plastic manufacturers. In cooperation, new materials, new forms, new approaches are developed and their marketability tested. Currently, we are focusing on a new type of jounce bumpers for suspension struts, which together with the manufacturer DuPont are being developed up to series production. This innovative automobile application requires a high-precision production process, as durably guaranteed by Ossberger.

Did you know ...

stagecoaches reached an average speed of 3.4 km/h that at the end of the 18th century? To travel from Paris to Geneva, you had to plan 158 hours of travel time. In addition, the coaches jolted so much that "body and soul were in danger of getting separated". The automotive present is much more pleasing. Paris-Geneva can be reached in under five hours and without any jolting. This is also due to the pressblower injection blow moulding technology from OSSBERGER, which protects shock absorbers and drive joints.